With a wide range of dyes for cellulosics and polyester, DyStar offers BAT solutions to the demands of the fashion industry.

For Polyester, our high quality disperse dyes are the perfect solution. Our auxiliaries complement our dyes throughout the entire process for best results, reduced environmental footprint and comfortable finishes.

Benefits at a Glance

- Wide range of shades available

- High brilliancy

- Very good fastness performance

- Competitive product cost and cost saving solutions

econfidence®

- Water and energy saving solutions

- Compliance with different Brand’s & Retailer’s Restricted Substance Lists

- Compliance with international regulations

- Compliance with voluntary standards

Recommended Dyes

For Cellulosics

Levafix® CA

Reactive dyes for high fastness performance on fashion articles

Free of p-CA and other regulatory controlled amines; enhanced properties, superior Black color constancy

Reactive dyes for competitive solutions with good fastness profile

Other selected Levafix and Remazol dyes

For Polyester

Dianix® CC

Disperse dyes for reliable and competitive Polyester

Other selected Dianix dyes

Recommended Auxiliaries and Processes

Brightening agents for brightest whites on cellulose and polyester.

Evo® Care

Evo finishing products for wellness effects

Industry Solutions

Formal Wear (Wool Solutions)

Our range of wool dyes meets all requirements. The history of wool dyeing is a story of innovation. The aim has always been to develop new dyes and application processes which improve quality and fastness properties.

DyStar provides a full range of dyes to meet all requirements in the dyeing of wool. – From high-quality and economical standard dyes to innovative problem-solvers.

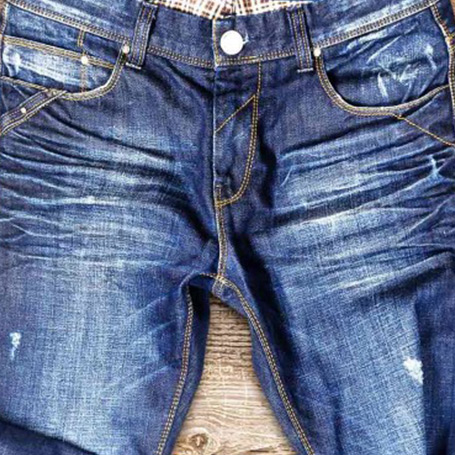

Denim Solutions

A complete, innovative and sustainable solution for denim.

DyStar, the innovation leader for the denim industry, offers a variety of products and services to support their customers in creating fashionable and sustainable garments. They provide the most complete denim package with a range of dyes and complimenting auxiliaries for the entire process, from pretreatment to the laundry processes of the apparel. DyStar uses their experience to help their customers achieve high quality products and also reduce their costs and environmental impact.

Color Communication

Color Solutions International is the leading provider of color standards and color communication tools.

DyStar’s color communication devision, CSI, provides retailers and brands with a variety of flexible color options and services.

Melange Effects

Novel cellulose fiber blends for Melange Effects

Danufil Proshade Melange yarns – an innovation by Linz Textil – are a blend of two viscose fibers, one of them is Danufil Deep Dye. Danufil Deep Dye contains a permanent cationic charge which gives it a different affinity to anionic dyes. Because of the different affinities of the fibers to anionic dyes flexible Melange dyeings are possible which provides highest flexibility and time savings.

Antique Effects

A complete, innovative and sustainable solution for denim.

With DyStar’s new Lava Dye Antique range and process, it is possible to get “worn look” after dyeing with acceptable fastness levels. It provides high laboratory to production correlation and also very good re-producibility because of high fixing level and levelness.

Sustainable Solutions

Sustainable Fashion. Sustainability is our commitment at the DyStar Group, both in how we run our own organization, our production, logistics, as well as in the products and services we offer to brands, retailers and their industry partners.

DyStar dyes and chemicals are engineered to meet legislation like REACH, voluntary regulation or relevant RSLs of well-known brands and retailers.

Printing Solutions

Greening your production with DyStar Digital Printing Solutions. DyStar is a leading supplier of innovative digital textile printing solutions for the industry.

We offer extremely purified dyes manufactured in our modern production sites. Our technology team constantly improves the quality of our inks in our modern R&D laboratories.

Comfort For Fashion

DyStar’s Evo® finishing products provide solutions for a variety of requirements of the textile industry. Together with our Evo product pages, we also offer labels for our customers to present the high quality standard on the finished product.

Modern life provides us with daily challenges, and increased pressure on our leisure time. Today, we expect not just great comfort from textiles, but garments which keep their shape and size and look good for longer. With this in mind, DyStar offers the Evo Comfort concept. It brings together the reassurance of a high quality finish with additional functionality.